Efficient logistics with AI and innovative warehouse management

Thanks to innovative technologies and artificial intelligence (AI), logistics is also currently undergoing a major transformation. From the warehouse to transport and delivery, processes are automated and optimized by AI.

This not only relieves the burden on logistics employees and drivers, but also speeds up processes and ensures greater efficiency, control and transparency while reducing costs. Denkinger is a leader when it comes to the use of artificial intelligence to optimize processes in transport, logistics and warehouse management. In this way, we can support you in mastering the major challenges on the market. With AI, we can adapt our offers precisely to your needs and continue to optimize them.

Our advantages

How digitalization at DENKINGER pays off for you

- Efficient production and transport optimization

- Simple capacity management

- Better demand forecasts and sales planning thanks to AI

- AI-based warehouse logistics

- Automated and highly flexible logistics

- Simple same-day delivery

- Better risk management

- AI-based systems for quality assurance

- More overview and control over all processes

- Transparent and controllable supply chains

- Event-based and dynamic route planning

- Intelligent route planning, such as avoiding traffic jams, minimizing accidents through low-risk routes, routes with few bends…

- Automatic detection of customer waiting times

- Forecasts of possible transportation delays

- Valuable support for all logistics employees

- Minimization of errors

The self-learning supply chain

Imagine this: Your products come out of production, but the warehouse is overflowing and there are no trucks available for transportation. Or goods arrive at the warehouse but cannot be accepted because all the ramps are full and a number of trucks also want to unload.

Thanks to artificial intelligence, the supply chain is now becoming “intelligent” and preventing precisely these delays and problems. With the help of AI, logistics can be managed in such a way that the required resources and capacities are available on time and to the required extent. This ensures smooth and efficient processes and reduces stress for your employees.

More transport safety through artificial intelligence

AI also plays a major role in transportation. For example, route planning can be dynamically optimized. Snow at your destination? Or heavy rainfall? The AI always ensures that the driver is given the safest route in order to arrive at the destination on time. Evaluations of accidents and high-risk routes are also taken into account, as is energy-saving driving. Of course, recurring events are also taken into account. Whether it’s Christmas or vacation traffic or a large public festival – the AI knows where delays may occur before departure.

AI and warehouse management

Digitalization has brought many advantages, especially in the warehouse. From incoming and outgoing goods to picking, packing, stock transfer and inventory – all processes are now optimized thanks to AI. Thanks to an intelligent warehouse management system and innovative technologies such as sensors (RDID chips, OCR), shuttle/automated guided vehicles, pick-by-voice, pick-by-light, pick-by-scan, robots, smart glasses or drone inventory, artificial intelligence is increasingly transforming the warehouse into a “learning warehouse” and providing your logistics employees with efficient tools that make their work easier. It also makes it easier for you to keep track of all goods and processes relating to the warehouse.

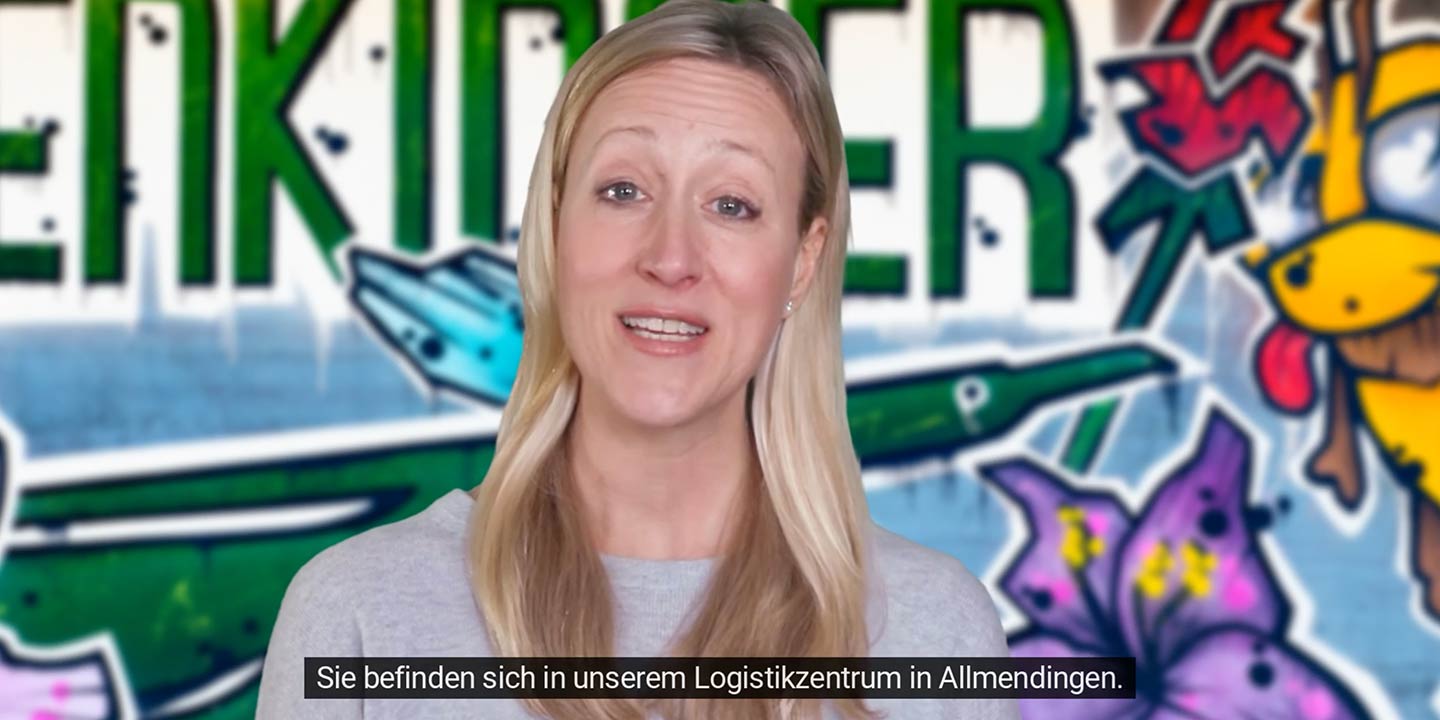

AI-supported info videos

A prime example of digital efficiency in day-to-day logistics is the smooth overcoming of language barriers. With the support of artificial intelligence, videos containing essential information for drivers can be created with relatively little effort.

Do you have any questions?

Do you need more information on the use of AI or warehouse management at DENKINGER? Or would you like to find out more about DENKINGER-Digital in general?

Send us an e-mail to support@denkinger-logistik.de or call us on Tel. 07391 / 70880